Home

Il Coppo di Alubel

Coppo is a made-to-measure tile shaped metal sheet that enables the realization of new roofs and the restoration of old ones. It can be made with various materials and also includes a wide range of accessories that have been designed specifically to adapt to the geometry of the profile.

Read more

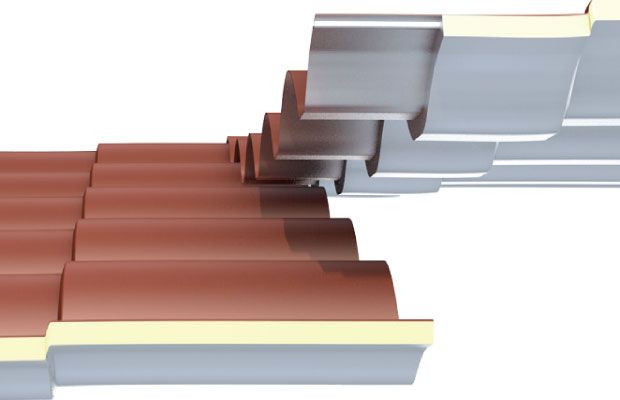

IsoCoppo Tek

IsoCoppo Tek is the new “reinforced” tile shaped pressed sheet: a core of high density polyurethane foam is applied during the manufacturing process which increases the product’s intrinsic properties. Its main characteristics are: lightness, a wide range of accessories and standard lengths with overlapping and polyurethane already removed.

Read moreIsoCoppo Piano

IsoCoppo Piano was the first tile shaped insulated panel introduced to the market: its shape was conceived right from the start to look as much as possible like a traditional Roman tile. This resulted in the creation of the tile shaped pressed panel with an average insulating material the thickness of which is the highest in the market.

Read more

Coppo Roma

Coppo Roma is the new system of Roman tile-shaped sheets that brings together the technology of metal and the tradition of clay roofs. Coppo Roma is not just a simple metal sheet but an integrated system to cover the roof, completed by a range of accessories and special items aimed at satisfying all project requirements.

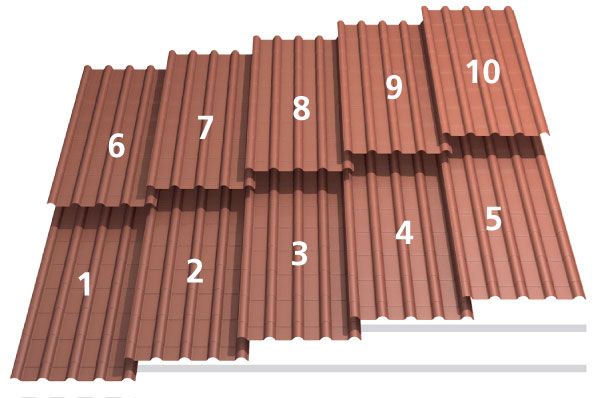

Read moreIl Coppo di Alubel

Is the tile shaped sheet produced to measure that enables the realization of new roofings and the restoration of old ones. It is produced in various materials and it includes also a wide range of accessories that have been developed specifically to adapt to the geometry of the profile.

Il Coppo is a metal sheet shaped like a tile and used to make roofs that are exactly like those of the typically Italian architecture. Its crowning glory is, first and foremost, an incredible lightness, equal to a tenth of the equivalent clay solution. Its considerable long life is also an added plus guaranteed by the choice of metal.

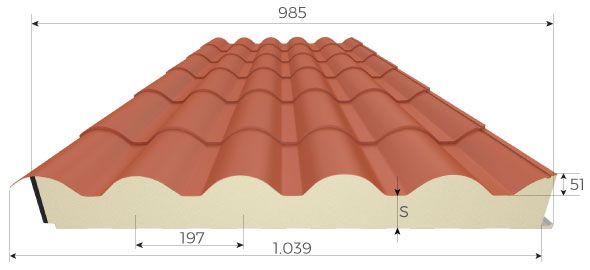

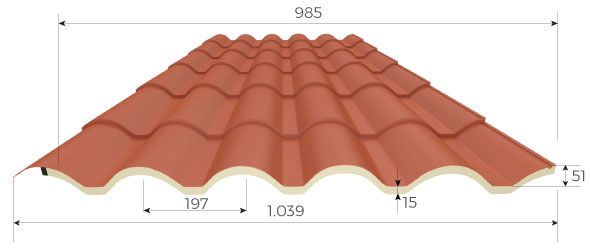

Features

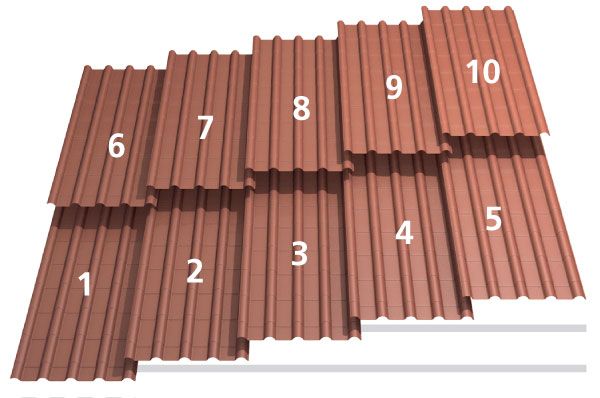

- Corrugation height:

- 51 mm

- Width:

- 985 mm

- Dimensions:

- min. 1550 mm, max 6030 mm

- Initial part:

- 90 mm

- Final part:

- 85 - 340 mm

- Sheet weight:

- in steel 5,7 kg/m2

in aluminium 3,2 kg/m2 - Minimum slope:

- 15%

- Material:

- prepainted steel, prepainted aluminium, copper.

- External finishing:

- coppo red, antiqued coppo red, sand, antiqued sand.

Other finishings upon request.

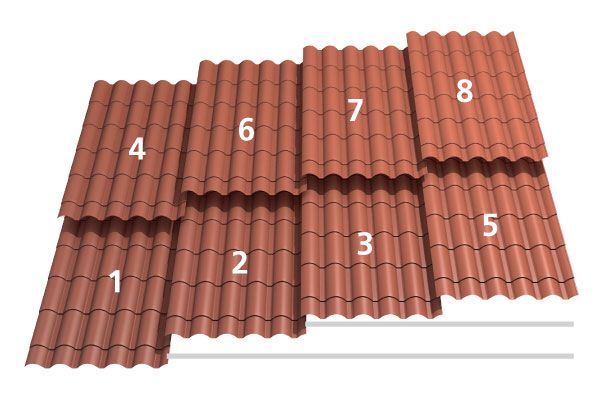

Lateral overlapping

Longitudinal overlapping

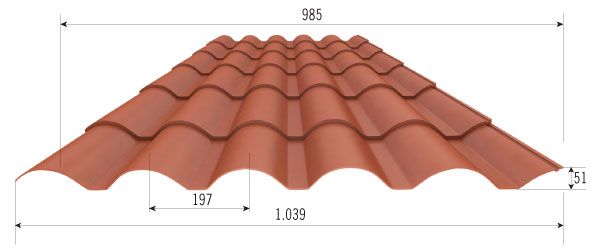

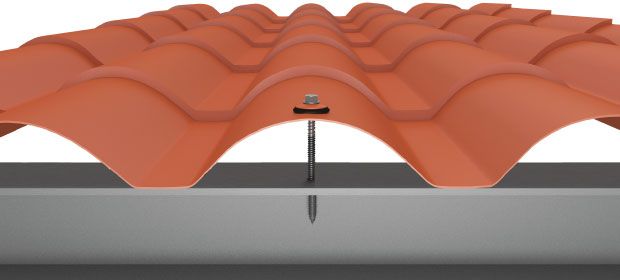

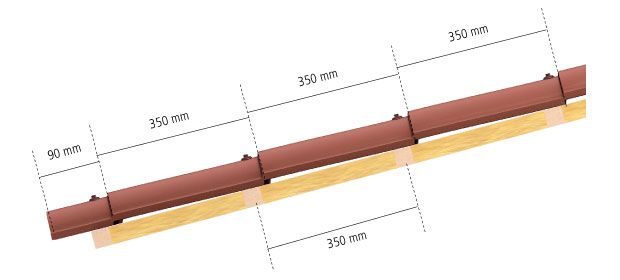

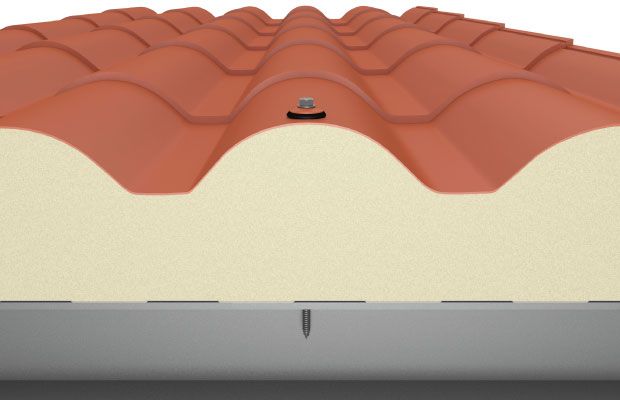

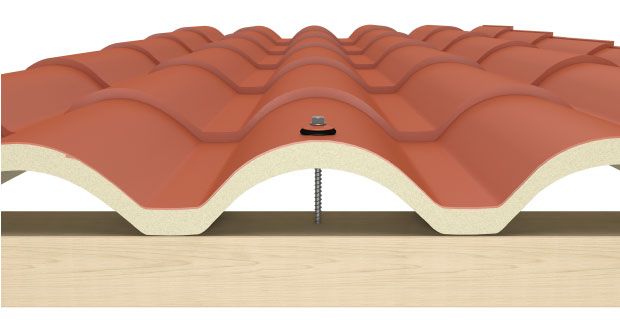

Fixing on wood structure

Fixing on metallic frame

Supports

Il Coppo di Alubel can be installed even on metallic frame than in wood structures; distance between span must be each 350 mm.

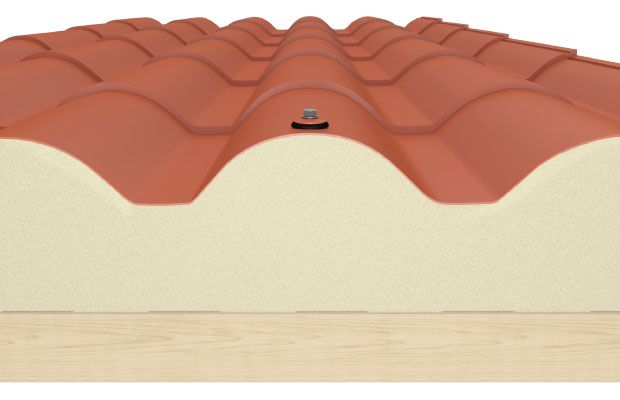

Installation

The installation of Coppo/IsoCoppo range is characterised by an extreme simplicity and quickness: the possibility to assemble sheets to measure means assembling many square metres in less time.

IsoCoppo Piano

It is the first tile shaped insulated panel introduced to the market: its shape was conceived right from the start to look as much as possible like traditional tiles.

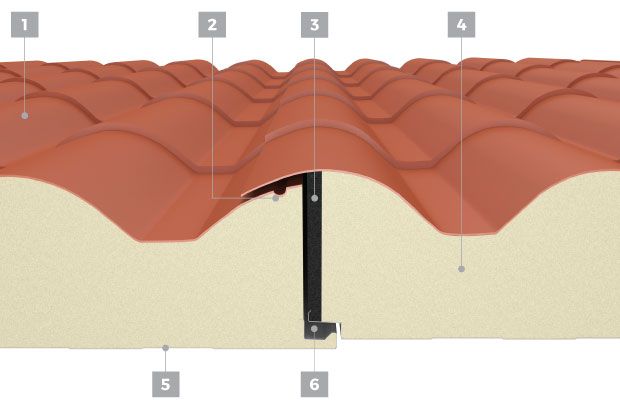

Each single roof now has to guarantee specific energy requirements which were unheard of only a few years ago: with this in mind Alubel designed Isocoppo Piano, the pressed, insulated, flat structural panel shaped like a tile. It is a classical sandwich panel with a double metal sheet and a polyurethane foam layer in between (density 35-40kg/m3) and has a far superior finish looking just like a traditional tile roof. In this way, Isocoppo Piano is suited to all applications, especially where greater sensitivity is required as regards to the surrounding landscape, whether it is town buildings (old town centres or in contexts of great worth) or a typically rural setting (farm houses, livestock sheds).

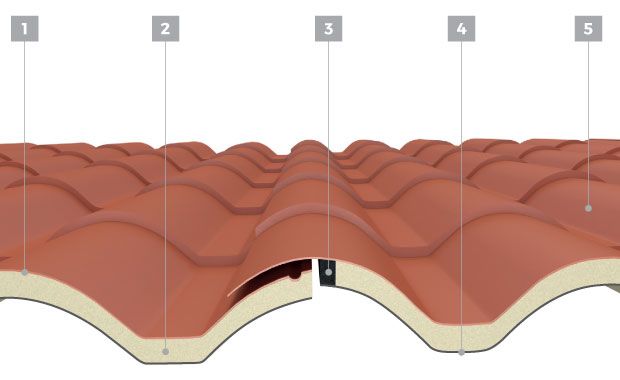

Panel components

- tile shaped external metal surface (steel, aluminium, copper)

- water drainage channel

- high thickness lateral seal (30 kg/m3)

- insulation made of constant density polyurethane foam

- internal surface with various finishings: white, with bituminous felt or aluminium foil without aesthetic function, and the new finishing painted wood

- condensation drainage channel

Features

- Dimensions:

- max 13.300 mm (moduli da 350 mm)

- Initial section:

- 175 mm

- Final section:

- 175 mm

- Overlapping:

- 130 mm

- Weight of the panel:

- in prepainted steel 10,3 kg/m2

in prepainted aluminium 7,7 kg/m2 - Standard thickness:

- 40 mm

- Average thickness:

- 65 mm

- Other thicknesses:

- 30 - 50 - 60 - 80 mm

- External support:

- prepainted steel, prepainted aluminium, copper.

- External finishes:

- tile red, antiqued tile red, sand, antiqued sand.

Different finishes on demand and according to specific conditions. - Internal support:

- Grey white, "Pireneo" white, faux cherry wood (painted), faux walnut wood (painted), ribbed aluminium, bituminized felt.

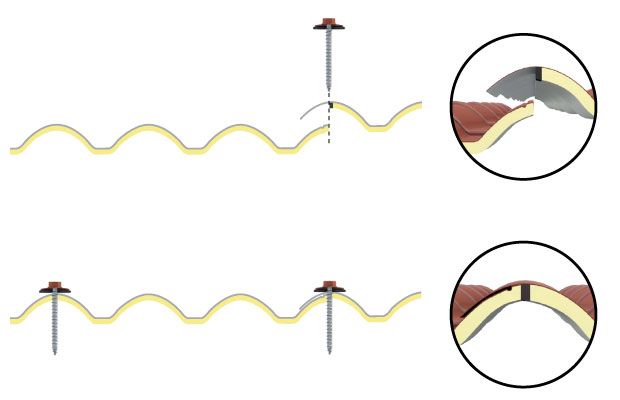

Fixing

Fixing on a wooden structure

Fixing on a metal structure

Heat insulation

From the point of view of heat insulation, the standard 40 mm version panels guarantee a transmission rate of U=0.377 W/mqK, but they are also available 100 mm thick with a transmission rate of U=0.189 W/m2K (value adequate to meet the strictest energy efficiency standards). The strong point of this solution is its load bearing capacity which, in the steel version with the standard 40 mm thickness can reach an allowable load greater than 300 kg/m2 for a span of 1.5 m meaning that it can be laid on sub-structures with larger spans. This does of course mean it is much quicker to lay making this solution ideal everywhere.

Supports

| Distance between supports |

IsoCoppo 40 mm steel 0,5 mm + steel 0,4 mm |

IsoCoppo 40 mm aluminium 0,7 mm + steel 0,4 mm |

|---|---|---|

| 1,50 m | 334 kg | 180 kg |

| 2,00 m | 195 kg | 167 kg |

| 2,50 m | 101 kg | 93 kg |

Load distributed evenly, expressed in daN/m2 for a double span and a downward load. Assessments carried out as per the ITC technical report no. 3962/RT/05, applying a 1.5 safety factor to the load corresponding to the strain, equal to 1/200 of the span.

IsoCoppo Tek

It is a monolithic insulated sheet made in copper, aluminium or prepainted steel with its own particular architectural design in the shape of a Tile.

IsoCoppo Tek is the new strengthened tile shaped sheet: a high density expanded polyurethane core applied during production allows to enhance the product characteristics.

Panel components

- Tile shaped external metal surface (steel, aluminium, copper)

- High density 15 mm insulation

- Lateral seal

- Internal aluminium foil without aesthetic function

- Polyester-based coating

Fatures

- Dimensions:

- (with 130 mm overlapping) 2230, 2580, 3280, 3980 mm

- Width:

- 985 mm

- Initial part:

- 190 mm

- Final part:

- 290 mm

- Overlapping:

- 130 mm

- Weights:

- in prepainted steel 5,7 kg/m2

in prepainted aluminiumn 3,2 kg/m2 - Insulation:

- polyurethane high density 60 kg/m3

- Insulation thickness:

- 15 mm

- Minimum slope:

- 15%

- Material:

- prepainted steel, prepainted aluminium, copper.

- External finishing:

- coppo red, antiqued coppo red, sand, antiqued sand.

Other finishings upon request

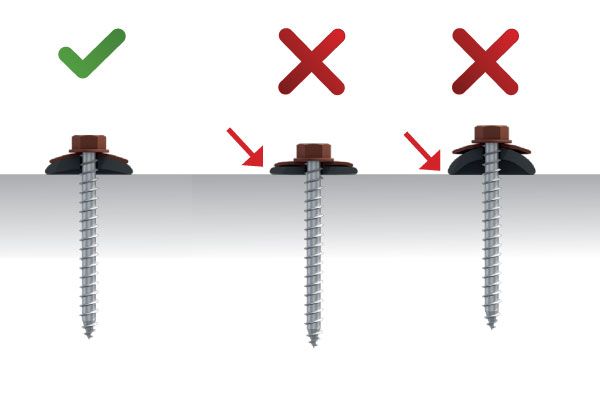

Fixing and overlapping

Fixing on wood structure

Longitudinal overlap

Lateral overlap

The lateral overlap of the sheet is quick and optimized thanks to the lateral seal.

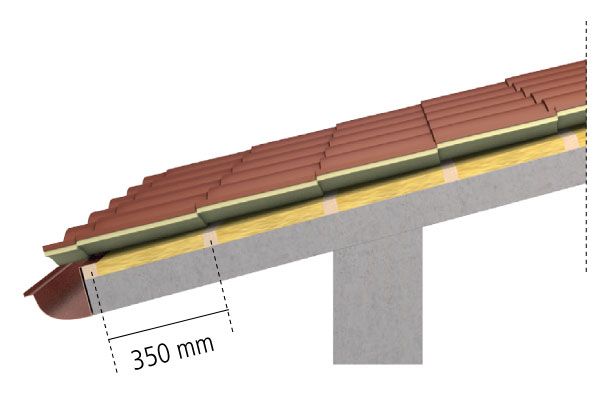

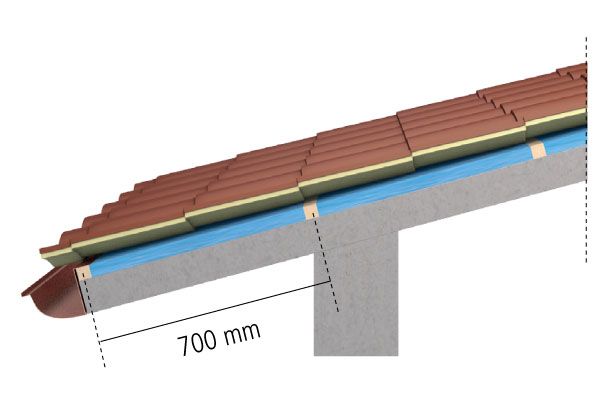

Supports

Installation on a flexible insulating medium

supports every 350 mm

Installation on a stiff insulating medium

supports every 700 mm

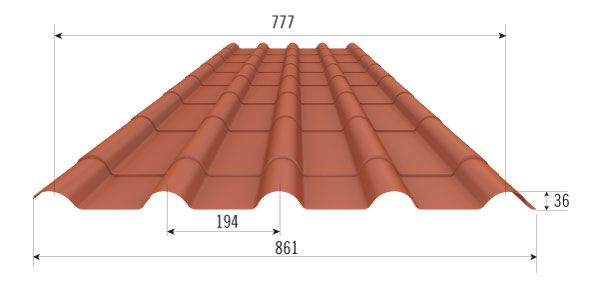

Coppo Roma

This is the technological roofing system in the shape of the traditional Roman tile.

Thanks to its research and development, Alubel spa, leader company in the field of metal roofing and cladding, has created Coppo Roma, the new system of tile-shaped sheets that brings together the technology of metal and the tradition of clay tile roofings. Coppo Roma is not only a metal sheet but an integrated system to cover the roof, completed by a range of accessories and special items aimed at satisfying all project requirements.

Features

- Height:

- 36 mm

- Width:

- 777 mm

- Weight:

- prepainted steel 0,5 mm = 5,2 kg/m2

prepainted steel 0,6 mm = 6,2 kg/m2

prepainted aluminium 0,7 mm = 2,5 kg/m2 - Minimum length:

- 1550 mm

- Maximum length:

- 6310 mm

- Standard lengths:

- 1550 / 2110 / 3230 / 3790 / 6030 mm

- Tile length:

- 280 mm

- Minimum slope:

- 15%

- Material:

- prepainted steel, prepainted aluminium, copper.

- Finishings:

- terracota red, terracota red "old tile", antique yellow, white grey, stone grey, anthracite grey

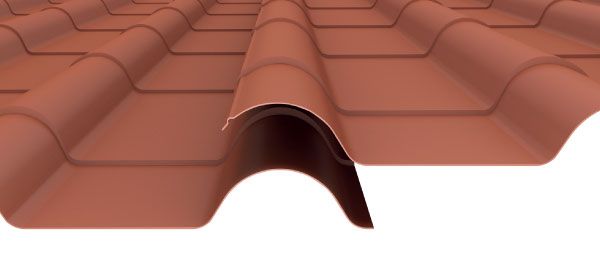

Lateral overlapping

Front overlapping

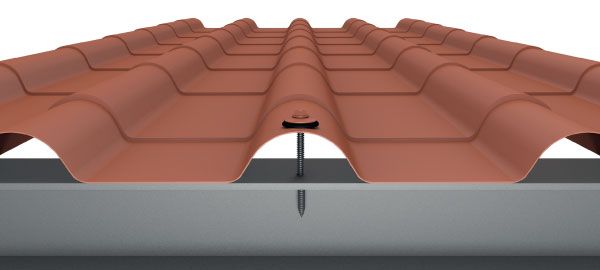

Fixing on a wooden structure

Fixing on a metal structure

Advantages

- high aesthetic value

- lightness

- waterproofing on low slope roofing

- ready for every structure

- length on demand

- full range of accessories

- easy to assemble

- no maintenance

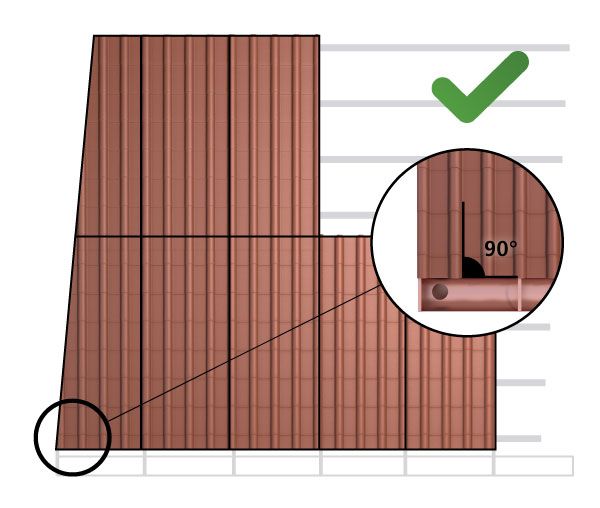

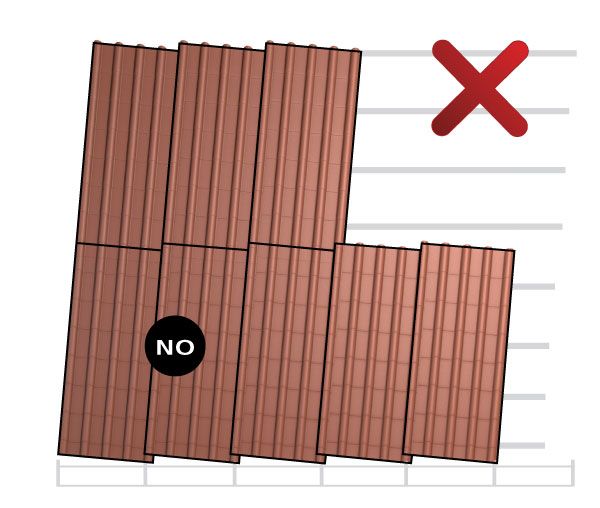

Installation

To lay the Coppo Roma sheets correctly it is essential to maintain a 90° angle with the edge of the gutter. If the pitch is not at right angles it is absolutely essential to keep the line parallel to the gutter. Any tolerances of squareness defects have to be kept to the side.

English

English  Italiano

Italiano  Français

Français  Español

Español  Português

Português